Improving Thermal Performance: The Impact of AMD's New APUs

Table of Contents

- Introduction

- The New APUs by AMD

- Thermal Paste Change

- Comparison with Previous AMD CPUs

- Pros and Cons of Using Thermal Paste

- The Importance of Price in Production

- The Process of Delidding the CPU

- Liquid Metal as a Thermal Solution

- Test Results and Temperature Comparison

- Is It Worth Delidding?

The New APUs and the Delidding Process

🔹Introduction

AMD recently unveiled its new APUs, the Raven Ridge series. These processors are already available in stores and have garnered a lot of attention, especially due to a change in the thermal paste used. In this article, we will discuss the impact of this change and delve into the process of delidding the CPU.

🔹The New APUs by AMD

The new Raven Ridge APUs introduced by AMD have caught the interest of many tech enthusiasts. These APUs come with a noteworthy change – they no longer feature soldered CPUs. Instead, AMD has opted for the use of regular thermal paste. This change has sparked debates and discussions among users and reviewers alike.

🔹Thermal Paste Change

Many reviewers have conducted tests and comparisons to gauge the impact of this change in thermal paste. One such review by ComputerBase compared the temperatures of the new Raven Ridge APUs with soldered AMD Ryzen CPUs. Surprisingly, the results did not show a significant difference in temperatures when using the stock AMD box cooler. This has led to mixed reactions from users who were expecting a bigger gap in temperatures.

🔹Comparison with Previous AMD CPUs

It is important to note that this is not the first time AMD has used thermal paste instead of solder. In the past, there have been instances where AMD APUs, such as the Trinity series, were also delidded. While the CPUs are relatively older, it is worth mentioning that APUs generally do not cater to the overclocking market and are not designed for extensive overclocking. Therefore, AMD's decision to use thermal paste can be seen as a cost-effective approach in production.

🔹Pros and Cons of Using Thermal Paste

The use of thermal paste in CPUs has its pros and cons. On the positive side, it is a more cost-effective solution during production. Additionally, the heat generated by APUs is not as high as that produced by heavily overclocked CPUs. Hence, the difference in performance between delidded and non-delidded CPUs might not be as significant as some may assume.

However, some users were disappointed with AMD's decision to opt for thermal paste, as they were expecting soldered CPUs. It is important to consider that the production cost plays a significant role, and AMD has likely chosen the more economical option. Moreover, the performance gain from delidding may not be worth the risks and potential damage to the CPU.

🔹The Process of Delidding the CPU

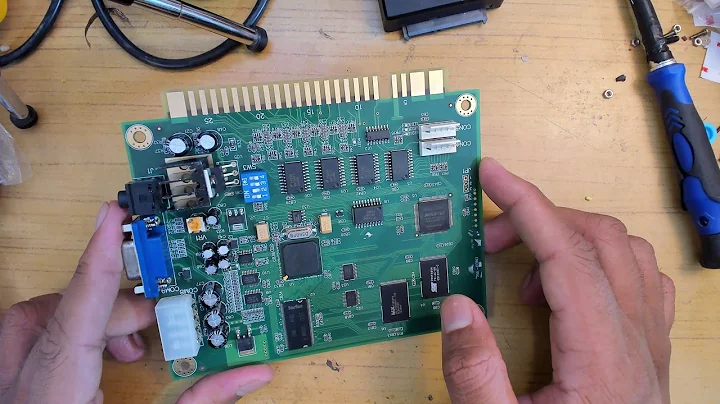

Despite the controversy surrounding the change in thermal paste, some users might still be intrigued by the idea of delidding their AMD APUs. The process involves removing the heat spreader from the CPU and replacing the thermal paste with liquid metal. This can potentially result in lower temperatures and better thermal performance.

To delid the CPU, various methods can be used. However, it is essential to exercise caution to avoid damaging the CPU. Using a vice or an adapter with screws can help stabilize the CPU during the delidding process. In some cases, users have even repurposed specific tools to assist in the delidding process. Commercially available kits with laser-cut templates and screws can also be utilized to ensure a safer delidding experience.

🔹Liquid Metal as a Thermal Solution

One popular alternative to thermal paste is the use of liquid metal as a thermal solution. Liquid metal has superior thermal conductivity compared to traditional thermal paste, leading to better heat dissipation. Applying liquid metal to the CPU can be a delicate process, as it requires a thorough cleaning of the CPU and careful application to achieve optimal results.

🔹Test Results and Temperature Comparison

After delidding the CPU and applying liquid metal, it is crucial to measure the impact on temperatures. testing the CPU under heavy load, such as in the Cinebench and Prime95 benchmarks, provides insight into the thermal performance improvement. Reviews and tests have shown that delidding the CPU and using liquid metal can result in noticeable temperature reductions, improving overall thermal efficiency.

🔹Is It Worth Delidding?

The decision to delid an AMD APU ultimately depends on the user's specific requirements and circumstances. If a system is already limited by cooling capacity, such as in small form factor systems or HTPCs, delidding and using liquid metal may provide a noticeable improvement in thermal performance. However, for most users, the potential risks and limited performance gains may not justify the process of delidding.

Highlights

- AMD introduces new APUs with a change in thermal paste usage.

- Debate arises regarding the impact of using regular thermal paste.

- Comparison shows minimal temperature differences between soldered and delidded CPUs.

- APUs are not designed for extensive overclocking, making the change in thermal paste cost-effective.

- Delidding involves removing the heat spreader and using liquid metal as a thermal solution.

- Liquid metal provides superior thermal conductivity, resulting in lower temperatures.

- Delidding APUs can improve thermal performance in cooling-limited systems.

- However, the process of delidding may not be worth it for most users.

FAQs

Q: Is delidding an AMD APU recommended for everyone?

A: Delidding an AMD APU is recommended for users with cooling-limited systems or those seeking the maximum potential thermal performance. For most users, the risks and limited performance gains may not justify the delidding process.

Q: Are there any commercially available kits for delidding CPUs?

A: Yes, there are commercially available kits with laser-cut templates and screws that can assist in the delidding process. These kits are designed to provide stability and safety during the delidding procedure.

Q: How does liquid metal compare to traditional thermal paste?

A: Liquid metal has superior thermal conductivity compared to traditional thermal paste, resulting in better heat dissipation and potentially lower temperatures. However, applying liquid metal requires careful cleaning and application techniques to avoid damage and achieve optimal results.

WHY YOU SHOULD CHOOSE TOOLIFY

WHY YOU SHOULD CHOOSE TOOLIFY