Unveiling the Surprise: Delidding the Raven Ridge - Ryzen 5 2400G for Massive Temperature Drops

Table of Contents

- Introduction

- The Surprise Over AMD's New APUs

- AMD's History with Thermal Interface Material (TIM)

- Cost Reduction Considerations for Low-End CPUs

- The Differences in Soldering and TIM Usage in APUs

- The Importance of Soldering for High-End Desktop CPUs

- Addressing Surprises and Confusion in the Comments

- testing the Before and After Temperatures with Delidding

- Introducing the Delidding Process

- The Safety and Effectiveness of Delidding AMD APUs

- Protecting the CPU Components during Delidding

- Applying Liquid Metal for Improved Thermal Conductivity

- Avoiding Excess Liquid Metal and Cleaning Residues

- Testing the Overclocked Settings with Delidding

- Comparing Temperature Improvements with and without Delidding

- Is Delidding Worth It? Considerations for Different Use Cases

- Offering Delidded AMD Raven Ridge CPUs

- Conclusion

📕 Introduction

In the world of computer processors, AMD has recently made waves with their new APUs (Accelerated Processing Units). These processors have sparked surprise and confusion among consumers and tech enthusiasts alike. One particular aspect that has raised eyebrows is the use of conventional thermal interface material (TIM) instead of soldering. In this article, we will explore the reasons behind this choice, delve into the history of AMD's TIM usage, and discuss the impact on performance and overclocking. Additionally, we will explore the potential benefits of delidding these APUs and address questions regarding the safety and effectiveness of this process.

📗 The Surprise Over AMD's New APUs

When AMD launched their new APUs, many people were caught off guard by the fact that these CPUs were not soldered but instead utilized conventional thermal interface material (TIM). This surprise was evident in the reactions of reviewers and YouTubers who expressed their astonishment in various videos and articles. However, it is important to note that AMD has previously used TIM on their APUs, especially on low-end and budget models. It is only the high-end desktop CPUs that have traditionally been soldered. This cost-saving measure allows AMD to offer affordable CPUs without compromising too much on performance.

📘 AMD's History with Thermal Interface Material (TIM)

To understand the surprise surrounding AMD's new APUs, it is essential to delve into their history with TIM usage. Previous generations of AMD APUs, such as the Trinity and Kaveri, also employed TIM rather than soldering. As such, the use of TIM in the new Raven Ridge APUs should not come as a surprise to those familiar with AMD's product line. These budget-oriented APUs target a different market segment than high-end gaming CPUs, which is why AMD made the strategic decision to use TIM for cost reduction purposes without sacrificing too much in terms of performance.

📙 Cost Reduction Considerations for Low-End CPUs

The use of conventional TIM instead of soldering in AMD's low-end APUs is a cost-saving measure that helps reduce the manufacturing expenses. With these budget CPUs targeting price-conscious consumers and entry-level systems, AMD needs to strike a balance between performance and affordability. By utilizing TIM, which is less expensive than the soldering process, AMD can keep the prices competitive without compromising the overall functionality of the processors. This approach allows AMD to cater to a wider range of customers who prioritize budget-friendly options over cutting-edge performance.

📚 The Differences in Soldering and TIM Usage in APUs

While some AMD APUs utilize conventional TIM, others are still soldered. This discrepancy in soldering and TIM usage can be attributed to various factors, including power delivery design, thermal design power (TDP) requirements, and other processing considerations. The decision to solder or use TIM is not solely dependent on the specific APU model but rather on a combination of factors that the AMD engineering team carefully assesses. By aligning the thermal design with the intended performance and power characteristics of the APU, AMD ensures optimal functionality and cost-effectiveness in their CPU lineup.

📕 The Importance of Soldering for High-End Desktop CPUs

In contrast to the budget-oriented APUs, AMD's high-end desktop CPUs have traditionally been soldered. This choice is primarily driven by the performance demands of the high-end market segment. Gaming enthusiasts, content creators, and professionals who require top-of-the-line CPUs expect the highest levels of performance and thermal efficiency. Thus, soldering is essential as it provides superior heat transfer capabilities, ensuring that the CPUs can handle intensive tasks and overclocking without overheating. The soldering process creates a direct and efficient thermal pathway between the CPU die and the heat spreader, maximizing heat dissipation.

📗 Addressing Surprises and Confusion in the Comments

Following the launch of AMD's Raven Ridge APUs, the comment section on various platforms was filled with surprise and confusion regarding the use of TIM instead of soldering. Some viewers were genuinely taken aback by this choice, while others questioned the rationale behind it. It is essential to address these concerns and provide Clarity on the matter. As Mentioned earlier, AMD has a history of using TIM in their APUs, especially those targeting the budget and low-end market. Therefore, it is not an entirely new approach for the company. The decision to use TIM in Raven Ridge APUs is rooted in cost reduction considerations while still maintaining satisfactory performance capabilities for the intended market segment.

📘 Testing the Before and After Temperatures with Delidding

To investigate the impact of delidding on AMD's Raven Ridge APUs, we conducted a series of tests to compare the temperatures before and after the delidding process. By removing the heat spreader and applying liquid metal thermal paste, we aimed to improve the thermal conductivity and dissipate heat more effectively. Our testing focused on both stock and overclocked settings to provide a comprehensive analysis of the temperature improvements achieved through delidding. The results shed light on the potential benefits and drawbacks of this process for users looking to optimize the cooling performance of their APUs.

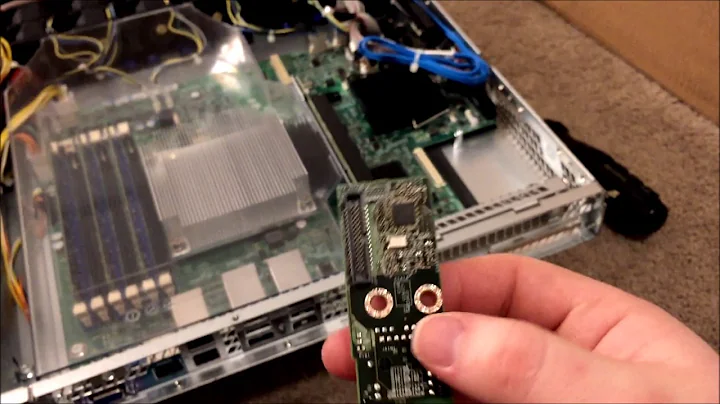

📙 Introducing the Delidding Process

Delidding involves removing the heat spreader from the CPU and replacing the thermal interface material (TIM) with liquid metal, which has significantly better thermal conductivity properties. This process aims to enhance heat dissipation and potentially lower the CPU temperatures, allowing for improved performance and potential overclocking headroom. While delidding may void the warranty of the CPU, it offers users the opportunity to optimize thermal performance on their own terms. It is important to approach delidding with caution and ensure proper safety measures are taken to avoid any damage to the CPU.

📚 The Safety and Effectiveness of Delidding AMD APUs

Delidding AMD APUs can provide notable improvements in thermal performance, but it is crucial to proceed with caution to ensure the safety of the CPU. The process involves using tools such as a delidding tool or a specially designed adapter to carefully remove the heat spreader without causing any damage to the CPU die or other components. It is recommended to follow step-by-step instructions and exercise patience during the delidding process. Furthermore, applying liquid metal thermal paste must be done with care to prevent excess spillage, which could damage the CPU or surrounding components. When done correctly, delidding can result in lower temperatures and improved overclocking capabilities.

📕 Protecting the CPU Components during Delidding

During the delidding process, it is essential to protect the CPU's sensitive components, such as the surface-mounted components and solder pads, from damage. Clear nail polish can be used to safeguard these areas by creating a protective barrier against accidental contact with tools or thermal compounds. By carefully applying a thin layer of clear nail polish, users can ensure that the delicate components remain intact and functional throughout the delidding process. This simple precaution adds an extra layer of protection, reducing the risk of unintentional damage to the CPU.

📗 Applying Liquid Metal for Improved Thermal Conductivity

One of the main advantages of delidding is the opportunity to replace the stock thermal interface material (TIM) with liquid metal thermal paste. Liquid metal offers significantly higher thermal conductivity compared to conventional thermal pastes, allowing for more efficient heat transfer. The application of liquid metal should be done with precision and caution to avoid spills or excess amounts interfering with nearby components or pins. It is crucial to follow the recommended guidelines for applying liquid metal, such as gently massaging it into the CPU die surface and ensuring a thin layer for optimal heat dissipation.

📚 Avoiding Excess Liquid Metal and Cleaning Residues

When applying liquid metal, it is essential to avoid applying too much paste, as excess amounts can lead to short circuits or interfere with nearby pins. Gentle massaging and spreading of the liquid metal across the CPU die surface help ensure even coverage while minimizing the risk of spills. If excess liquid metal is Present, using acetone on a cotton swab or cloth can remove the excess without damaging the CPU or surrounding components. Thoroughly cleaning any residues left behind from both the heat spreader and CPU surface ensures a clean and efficient thermal interface for improved heat dissipation.

📙 Testing the Overclocked Settings with Delidding

In addition to testing the stock settings, we also analyzed the impact of delidding on overclocked settings. By pushing the CPU beyond its factory-set frequency and voltage limits, we aimed to simulate a Scenario where increased thermal efficiency would be crucial. Our tests involved running the CPU at 3975 MHz with a voltage of 1.44V. This setup allowed us to evaluate the effectiveness of delidding in managing temperature levels during demanding tasks and stress tests. The results provide valuable insights into the potential benefits and thermal improvements achievable through delidding, particularly in overclocked settings.

📘 Comparing Temperature Improvements with and without Delidding

Comparing the temperature improvements obtained through delidding with stock and overclocked settings can provide a comprehensive understanding of the benefits for different usage scenarios. In our tests, we observed significant temperature reductions across both scenarios when delidding was applied. For stock settings, the maximum CPU temperature in Cinebench r15 decreased by 7 degrees Celsius, while the temperature in prime95 26.6 with a setting of 12K saw a reduction of 12 degrees Celsius. In overclocked settings, the benefits were even more noticeable, with temperature reductions of 10 and 15 degrees Celsius in Cinebench r15 and prime95 26.6 with a setting of 12K, respectively. These improvements highlight the potential for enhanced thermal performance and increased overclocking headroom with delidding.

📕 Is Delidding Worth It? Considerations for Different Use Cases

The decision to delid an AMD Raven Ridge CPU ultimately depends on the individual's specific use case and priorities. For users building compact systems or limited by cooling options, delidding can significantly improve thermal performance by reducing CPU temperatures. This improvement allows for more efficient cooling and potentially quieter operation. Additionally, delidding can provide a modest improvement in clock speeds, albeit usually around 25 MHz. However, for users seeking extreme overclocking or expecting drastic temperature reductions, delidding may not offer a significant advantage. It is important to weigh the potential benefits against the risks and warranty implications before deciding whether delidding is worth pursuing.

📗 Offering Delidded AMD Raven Ridge CPUs

To cater to users interested in delidded AMD Raven Ridge CPUs, we at Caseking will be offering a selection of delidded processors. These processors have undergone the delidding process and will be available for purchase online in the coming days. Additionally, we will provide an upgrade kit for users who wish to delid their own CPUs. The kit includes a piece of laser-cut acrylic and an M6 x 60 screw, allowing for safe and effective delidding of AMD APUs. By offering these options, we aim to provide enthusiasts with a convenient and reliable solution for optimizing the thermal performance of their CPUs.

📘 Conclusion

The use of conventional thermal interface material (TIM) in AMD's Raven Ridge APUs has surprised many, as some expected soldering to be the norm. However, AMD's history with TIM usage in their APUs, specifically in budget-oriented models, should provide context for this choice. By employing TIM in low-end CPUs, AMD achieves cost reduction while still delivering satisfactory performance. For users seeking improved thermal performance, delidding offers a potential solution. Through the careful removal of the heat spreader and application of liquid metal thermal paste, delidding can lead to lower temperatures and enhanced overclocking capabilities. The decision to delid should be based on individual preferences and usage scenarios, considering the potential benefits and warranty implications.

1.4M

1.4M

16.95%

16.95%

5

5

27.1K

27.1K

9.92%

9.92%

22

22

< 5K

< 5K

17.89%

17.89%

4

4

15.6K

15.6K

66.97%

66.97%

4

4

874.9K

874.9K

22.98%

22.98%

12

12

5.5K

5.5K

62.75%

62.75%

7

7

11.1K

11.1K

38.23%

38.23%

2

2

< 5K

< 5K

13

13

< 5K

< 5K

31.34%

31.34%

4

4

61K

61K

31%

31%

3

3

247.3K

247.3K

26.72%

26.72%

5

5

14.5K

14.5K

62.5%

62.5%

2

2

170.2K

170.2K

45.37%

45.37%

12

12

WHY YOU SHOULD CHOOSE TOOLIFY

WHY YOU SHOULD CHOOSE TOOLIFY